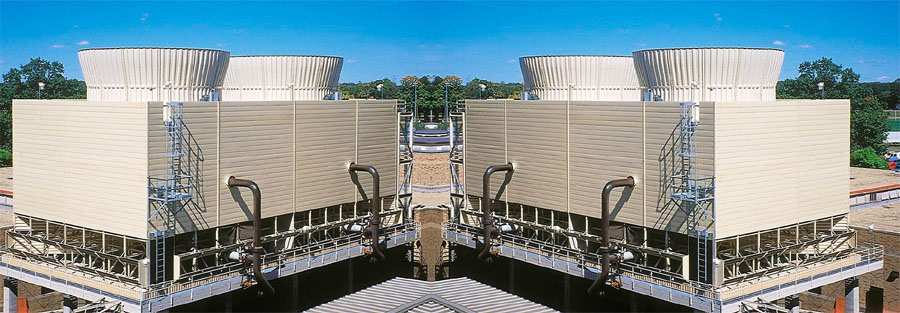

The BrapuBPO-IN industrial cooling tower series products are manufactured according to German cooling tower standards and rely on mechanical forced ventilation for cooling towers. A device that dissipates waste heat generated in industry or refrigeration and air conditioning through evaporation. Dry (low enthalpy) air enters the cooling tower from the intake network after being pumped by a fan; High temperature water molecules with high saturated vapor partial pressure flow towards low pressure air, and moist (high enthalpy) water is sprayed into the tower by the self seeding water system. When water droplets come into contact with air, on the one hand, due to the direct heat transfer between the air and the air, and on the other hand, due to the pressure difference between the surface of the water vapor and the air, evaporation occurs under the action of pressure. Currently, in order to remove the latent heat of evaporation, the heat in the water is carried away, which is called evaporation heat transfer, thus achieving the purpose of cooling. The single tower processing water volume of industrial cooling towers exceeds 1000m3/h. Brapu has achieved streamlined airflow field, low energy consumption operation, and ultra-low drift water loss through the optimization design of the entire equipment and various components.